Maximizing the Tensile Strength of 3D printed Polymers

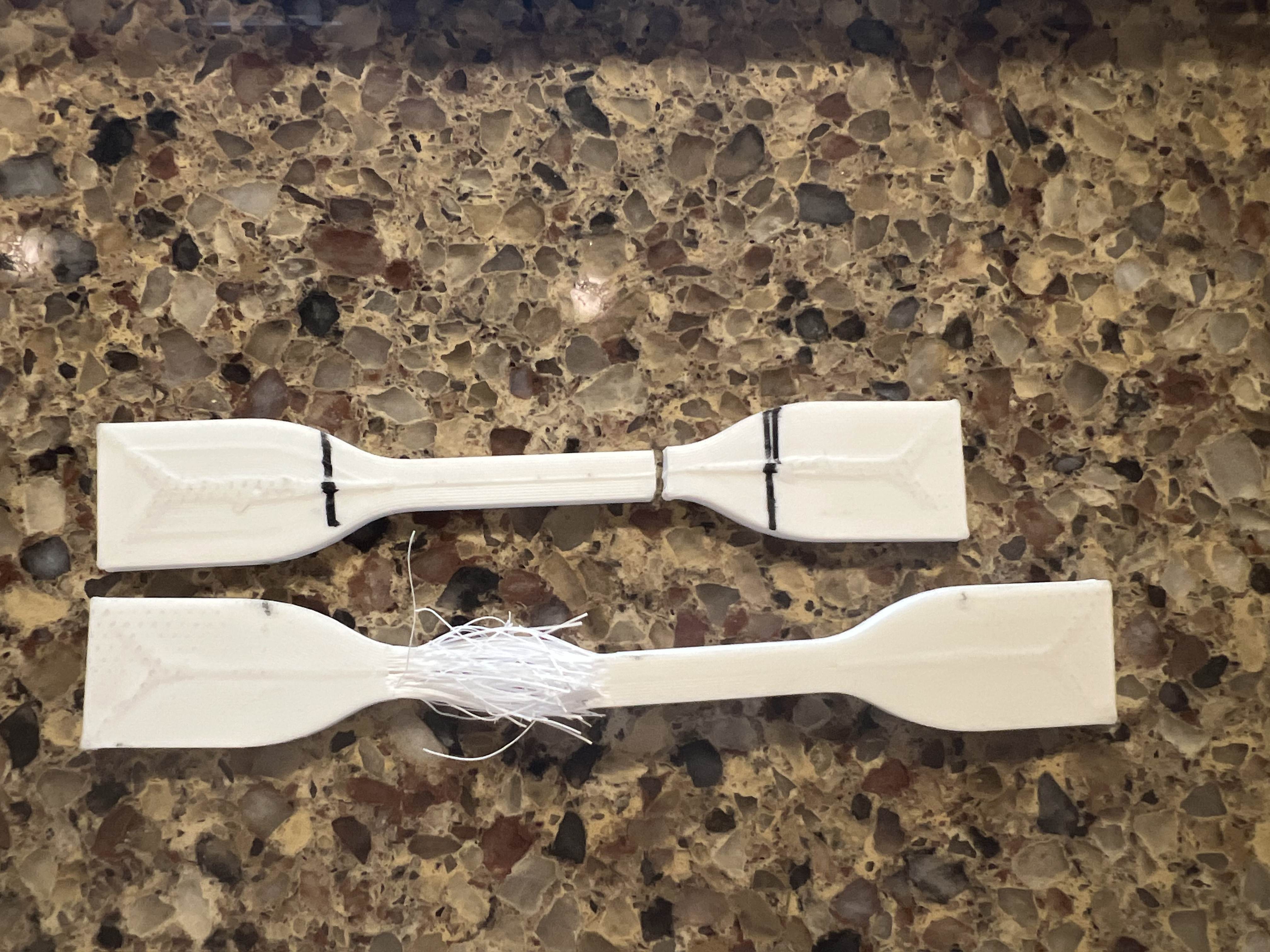

My research is focusing on characterizing the effect of several parameters on 3D printed materials. Most past and present research focuses heavily on layer height, print temp, and raster angle, but the reality is that there are many parameters that can impact a parts mechanical properties. Many -if not all- prints are done through a typical slicer, and this is where many critical issues arise and typically are going unrecognized. Additionally, past research struggles to maintain consistency and typically uses parameters that I would consider are detrimental to the results.

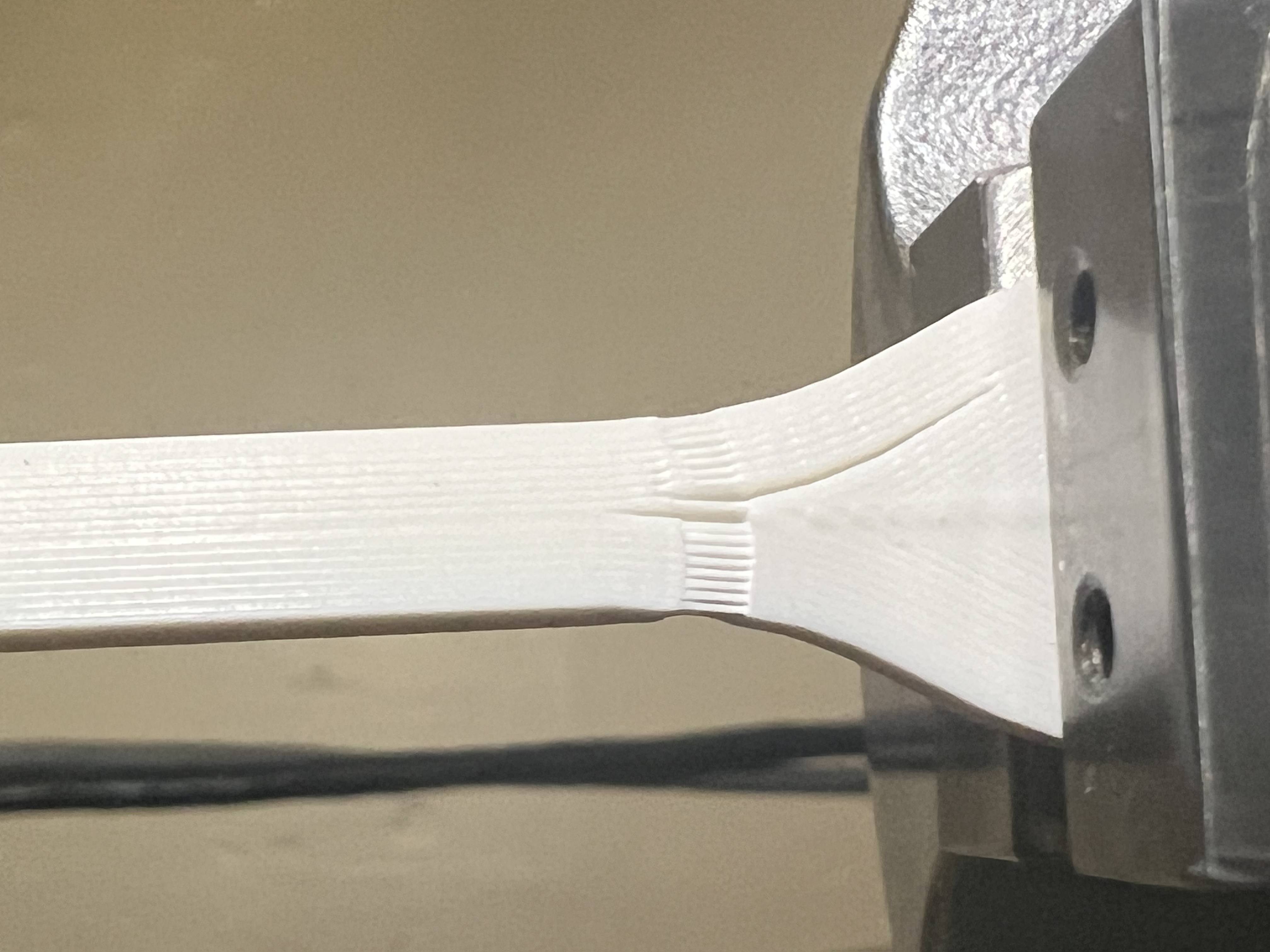

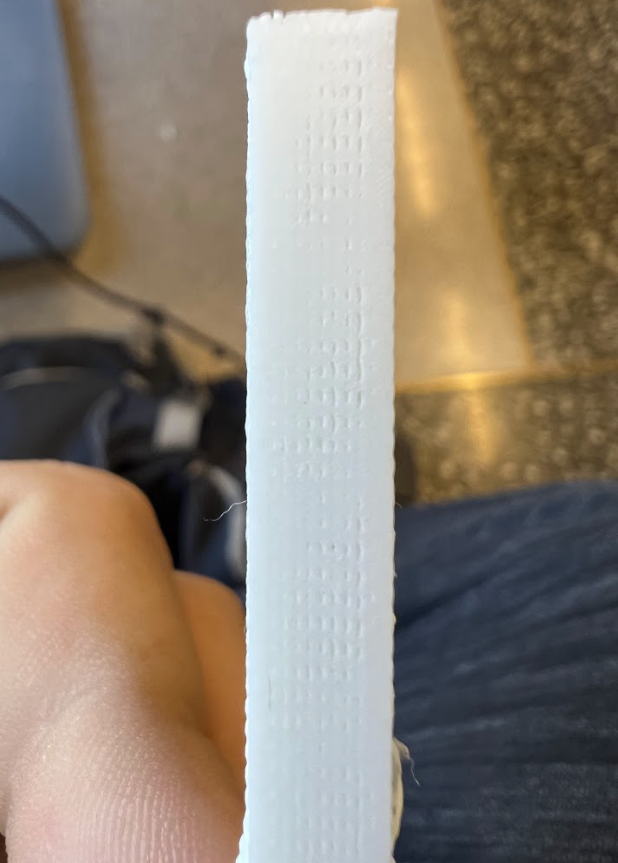

Some of the critical parameters of a print are: Z-Seam, Toolpathing, extrusion, and shells+etc. I won't bore you with the details but I'll include some pictures as examples. Slicers in their current state can only do too much, so I am going a step further by using a software to custom write G-Code so I can test differences in prints down to the individual print layer.